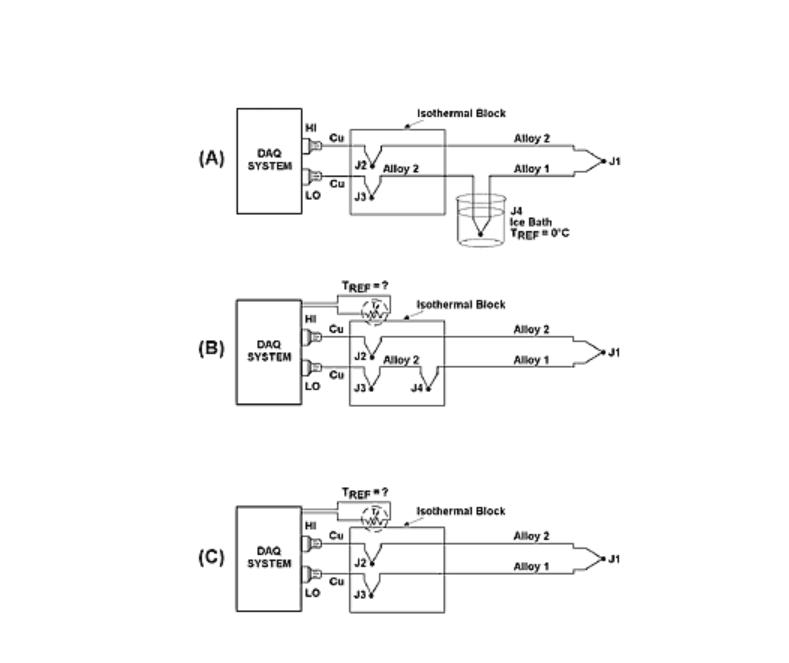

Imagine an electronic sensor technology that's simple, cheap, reliable, and 200 years old. Look no farther than the popular thermocouple. In the early 1800s, Thomas Seebeck discovered that the junction of two metals generates a voltage that depends on temperature. Many lab students have begun their association with thermocouples by exploring this relationship with a set-up similar to that shown in Figure 1. They measure an unknown temperature using a pair of thermocouple junctions, one of which is immersed in an ice water bath. After making voltage measurements, they determine the unknown temperature using a thermocouple look-up table. Today, engineers and scientists use electronic instrumentation that can accept dozens of thermocouple inputs, without requiring an ice bath reference or individual reference junctions. How this has been accomplished remains one of the least understood aspects of thermocouple use.A grasp of the principles involved can go a long way toward helping users avoid set-up and measurement errors with their own thermocouple systems.

Thermocouple Construction

A thermocouple consists of two wires of dissimilar metals joined at one end. This "hot junction" is used to measure an unknown temperature, while the "reference (cold) junction" and measurement hardware comprise the rest of the system.Although many metal combinations exhibit the Seebeck effect, a limited number have been established as industry standards because of their predictable output characteristics over a wide temperature range. The measured EMF is related to the difference in temperature between the hot and cold junctions (J1 and J4), and the types of metals used to construct the thermocouple. The result can be expressed by the following equation:

V = a(TUNKNOWN - TREF)

where a is the Seebeck Coefficient. This coefficient in highly non-linear, and varies for different types of thermocouples. It can be found in thermocouple references (usually in a table of voltage versus temperature), but modern electronic instruments and software generally automate the conversion of voltage to temperature, so the user needn't bother with a.

Simplifying the Measurement System

Modern thermocouple measurement instruments do not use the ice bath and corresponding reference thermocouple shown in Figure 1. This eliminates the need for a potentially large number of input channels for the references, not to mention the hassle of dealing with ice. Historically, the purpose of the ice bath was to force the reference junction to a known temperature (0°C), but any reference temperature can be compensated for, as long as we can measure it.

In Figure 1, it is obvious that connecting the thermocouple to a voltmeter input introduces more metal junctions into the circuit (J2, J3), both of which can generate additional thermal EMFs. Ideally, these terminals will be at the same temperature to eliminate additional error voltages, but this can be assured by mounting them to an "isothermal block" (Figure 2A). The isothermal block offers sufficient mass to withstand minor fluctuations in ambient temperature and maintain the attached terminals at the same temperature. This block can be integrated directly into the measurement hardware.

In Figure 2B, we move the reference junction (J4) onto the isothermal block, with the result that the instrument terminals and the reference junction are now at the same temperature. This temperature can be read with a sensor that does not require a reference junction, such as a thermistor or semiconductor temperature sensor.

The final step in simplifying this circuit is to eliminate the wire between junctions J4 and J3 (Figure 2C). For this step, we turn to the Law of Intermediate Metals, which states that a third metal inserted between two dissimilar metals of a thermocouple junction will have no effect on the output voltage, as long as those junctions are at the same temperature. By removing this wire, we achieve the input circuit commonly used for modern thermocouple instrument inputs (Figure 2C). Typically, multiple thermocouple inputs are populated on one isothermal block, and one temperature sensor used as the reference for all measurements.This minimizes the cost of adding a reference sensor for every channel. Note that thermocouple extension wire, and connector pins made from thermocouple metals, are available to permit a system assembler to maintain the proper sequence of metals in longer thermocouple runs.

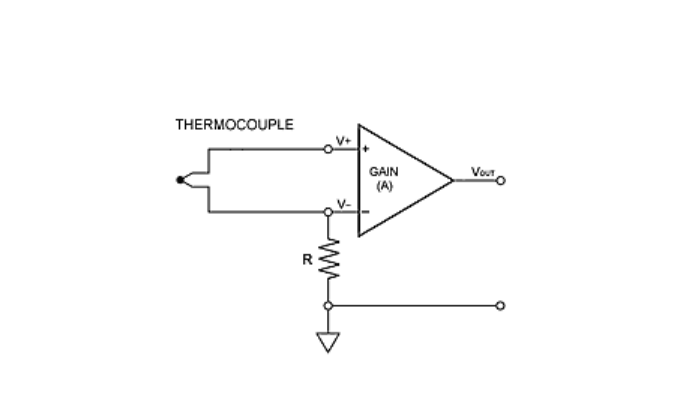

Now that we have a basic front end for an electronic thermocouple input module, what about other features that might help improve measurement results? For an answer, we need to consider the characteristics of a thermocouple's output signal. Thermocouples generate only microvolts per degree, and can be located far from the instrumentation, often in electrically noisy environments. Therefore, high gain and low-pass filtering are desirable in a thermocouple measurement instrument. Measurement integrity can be improved even more with a differential input (Figure 3). The differential configuration presents two very high impedance inputs to the thermocouple leads, and offers superior noise rejection as compared to a single-ended input. Note that Figure 3 shows a resistor connected from (V-) to ground. This resistor determines the actual input impedance of the thermocouple input, and also provides a bias current return path to ground, without which the amplifier might fail to operate correctly. This resistor sometimes must be added to a thermocouple input if it does not already exist in the instrumentation.

Concerning the conversion of voltage to temperature: the output of a thermocouple is non-linear, so any readout method must include a method for "linearizing" and scaling the thermocouple's output to produce accurate temperature readings. In modern instruments and data acquisition systems, this operation is normally performed by software, firmware, or other calibration techniques. Thus, the user is spared from tedious calculations.

As a result of the practices described above, a typical maximum speed for thermocouples is generally no more than a few readings per second. Most processes that require temperature measurement are slow by nature, so this is not a problem.

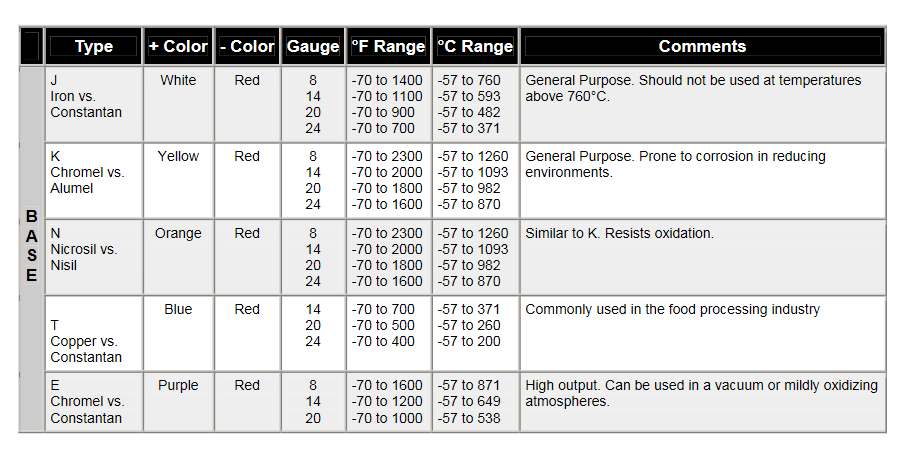

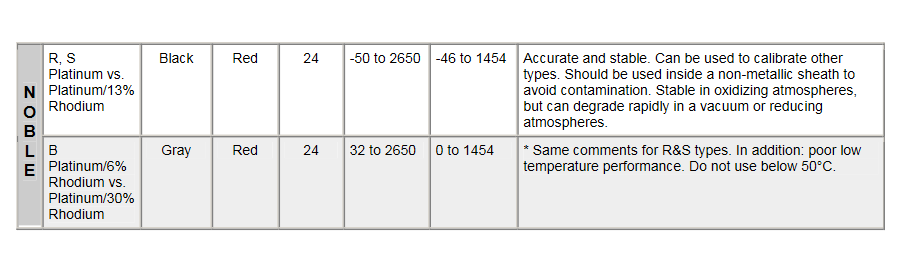

The final consideration in using thermocouples is to select a thermocouple type appropriate for the application. Collectively, thermocouples have a range of about -200° to over 2500°C with a typical accuracy on the order of ±1 to ±2°C, although the gauge and purity of thermocouple wire can affect range and accuracy. Table 1 summarizes the characteristics of several common thermocouple types. A variety of base and noble metals are used in thermocouples, in both pure and alloy forms. Common alloys include "Alumel" (a composition of nickel, aluminum, and manganese), "Chromel" (nickel and chromium), and "Constantan" (copper and nickel). Thermocouples can be used at elevated temperatures, and in atmospheres that can promote oxidation, reduction, corrosion, or contamination of the alloys, so careful selection of a thermocouple type can be crucial to longterm reliability and success.

In Conclusion

The thermocouple is an extremely versatile temperature measurement solution that offers reliability, ease of use, and low cost. Its accuracy and resolution are adequate for many industrial and research applications. In an emergency, thermocouples can be constructed in the field by simply stripping and twisting the conductors at one end of a length of thermocouple wire an impractical approach with other common types of temperature sensors. While there is clearly much more to be said about the thermocouple, the foregoing information can be helpful in evalsuating which is the best thermocouple for a given application, especially if it's been some time since your last temperature measurement lab.