Introduction

Electric vehicles are the transportation of the near future, with many governments and companies fully converting to electric vehicle fleets in the 2020s. All of these vehicles rely on battery packs to power them. These packs must be safe, reliable, and highly efficient, and manufacturers are responsible for ensuring every battery that they make meets strict standards. Manufacturers perform a variety of mechanical and electrical tests during the manufacturing process to ensure that the batteries are made correctly. Measurement solutions for these tests should be highly accurate, so they can best characterize the battery’s behavior and determine any potential for failure before the battery can be placed in a car. One common measurement made on batteries is the open circuit voltage (OCV). Keithley’s DMM7510 7½-Digit Graphical Sampling Digital Multimeter is a solution for accurately measuring the open circuit voltage of a battery cell.

Battery Cell Construction

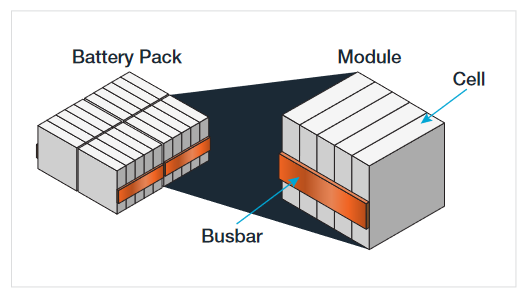

The battery packs that are placed inside of electric vehicles are comprised of modules, which include individual cells welded to a conducting busbar as shown in Figure 1.

Each cell has two electrodes, an anode and a cathode. These electrodes are isolated from each other with a special insulating membrane called the separator, and then the battery is filled with an electrolyte solution. The chemical compositions of all of the materials facilitate a flow of electrons between the electrodes. The flow of electrons constitutes electricity that can be used by connected devices. When nothing is connected to the electrodes, a voltage potential is present between the electrodes. This is the OCV potential.

Why Measure the Open Circuit Cell Voltage?

OCV measurements are used throughout the battery manufacturing process. One of the most important stages in cell manufacturing is the formation and aging process. During this phase, cells are cycled or repeatedly charged and discharged. Throughout the cycles, measurements are made to monitor the cells. Measuring the OCV of the cells provides several pieces of information to manufacturers. Changes in the OCV of the batteries over time can indicate the presence of defects in the cells. Shorts internal to the battery will cause the OCV of the battery to drop over time, until eventually the battery fails. It is important to detect these failures during the manufacturing process before they fail in the pack.

The OCV of the cell also plays a role in deriving other useful parameters about the battery operation, such as state of charge (SOC) and state of health (SOH). SOC and SOH are often used to report to the end user on how "ful" the battery is. It’s important that these calculations are accurate for the end user, and that relies on a good OCV-SOC model of the battery pack. During the aging process each cell must be accurately characterized so that similar cells are placed in a pack. This increases model accuracy and pack performance. The OCV can be measured at specific points during the charge/discharge process or between cycles over long periods of time. The performance of the battery is also heavily dependent on temperature, so, depending on the manufacturing requirements, the OCV may be characterized in many different test environments.

Measuring the Open Circuit Cell Voltage

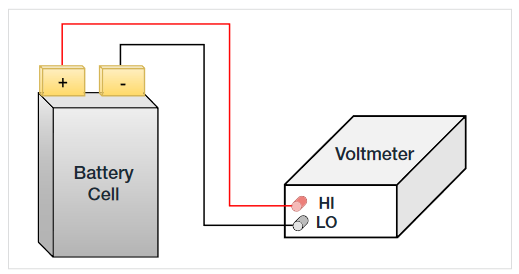

A sample circuit for measuring the OCV of the battery cell is shown in Figure 2.

The OCV of a single fully charged cell, is often small, less than 10V. The open circuit voltage of a fully charged battery pack is much larger, up to hundreds of volts. No load should be connected to the cell, as this would cause the cell to begin discharging, changing the measurement. An ideal voltmeter is an open circuit, and, in practice, the input resistance of the voltmeter should be high enough that no significant current flows, and the battery does not discharge. The voltmeter’s data sheet should list the input resistance specification. The battery should be charged or discharged and allowed to rest according to the manufacturers testing standard prior to measuring.

The aging process for battery cells can take hours to weeks of time, therefore it’s important to have an accurate voltmeter. A 7½-digit Graphical Sampling Digital Multimeter (DMM) can measure very small changes in the voltage, catching failures sooner and reducing critical testing time. This also helps ensure that batteries are characterized with the highest degree of accuracy possible, making for better packs in the future.

The Keithley Solution

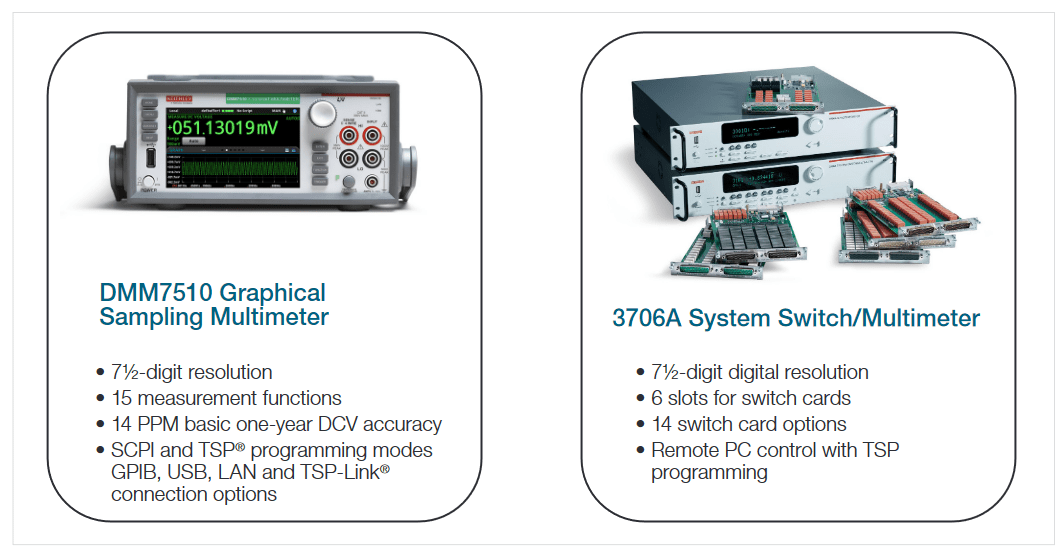

The Keithley DMM7510 is a great solution for measuring open circuit voltage. The DMM7510 is capable of measuring with 7½ digits of resolution, which translates to microvolts on the 10 V range. This allows you to detect minute changes in the OCV and make determinations faster, instead of waiting for a significant change in voltage. The DMM7510 comes with USB, GPIB, LAN and TSP-Link connections to make test automation quick and easy. With 15 measurement functions including current and temperature, the DMM7510 allows you to make more measurements with less equipment.

For applications that require testing multiple cells, the Keithley 3706A System Switch and Multimeter may be an ideal solution. The 3706A mainframe has six slots that can be customized with a wide range of switch cards. For example, a 3706A with six 3720 Dual 1x30 Multiplexer cards can be used to switch and measure up to 180 battery cells.

Conclusion

Battery cell open circuit voltage is one of the most important measurements made on the cell during manufacturing. High quality, reliable, and safe battery production starts with high quality testing. The Keithley DMM7510 provides the level of accuracy needed when measuring OCV to determine cell performance quickly and reliably.

Find more valuable resources at TEK.COM

Copyright © Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks or registered trademarks of their respective companies.

100121 1KW-73846-0