Introduction

With the increasing prevalsence of wireless technology and IoT devices, the need for rechargeable batteries that perform consistently over multiple charge cycles has grown exponentially. Consumers want to be certain that IoT controlled thermostats, lighting, security systems, and other appliances will continue operating long term and not degrade significantly over time. Thus, supplying safe, stable batteries to power these devices and meet the increasing demand is paramount.

One of the ways that batteries are exercised to determine reliability and lifespan is via battery cycle testing. Battery cycling involves charging and discharging a battery repeatedly for a specified number of cycles to determine its performance over time and after heavy usage.

This app note will discuss some of the features available starting in version 2.11.0 of the KickStart Software Battery Simulator App. This version of the Battery Simulator App introduces the new battery cycling functionality, and source measure unit (SMU) support allowing for both battery simulation and model generation in a one-box solution. In addition to discussing these new features, we will demonstrate the Battery Simulator App’s ability to test batteries and generate and simulate battery models using a wireless Ring Video Doorbell and Ring Security Camera.

The Previous Solution

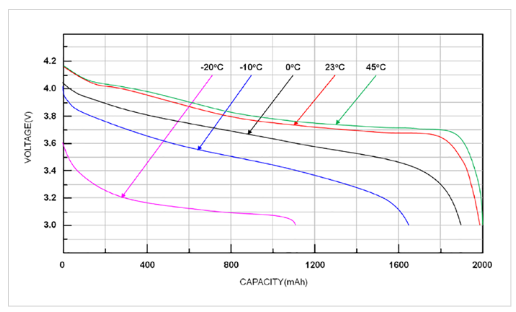

In a previous application note on this topic, Battery Optimization using Keithley 2281S and 2380 and KickStart Battery Simulator App, we discussed how to determine battery performance through discharge curve analysis and battery simulation. The discharge curve generated during battery model generation can give significant insight into a battery’s performance under different environmental conditions. Meanwhile, the simulation of these battery models allows for precise, repeatable test conditions. This can then be used to gauge the consistency of a device’s behavior as seen in Figure 1.

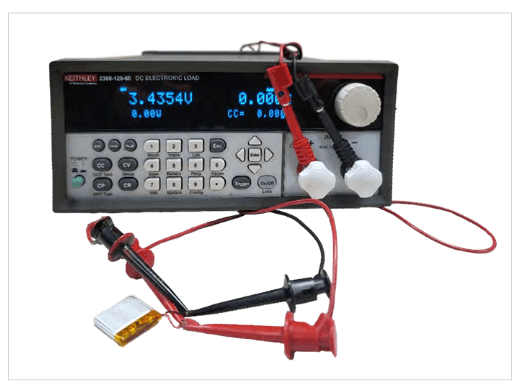

The previous solution offered by the KickStart Software Battery Simulator App involved generating a battery model using a 2380 Series Electronic Load and then simulating that model using a 2281S Battery Simulator.

This setup gets the job done but requires access to two separate instruments and does not offer functionality beyond battery model generation and battery simulation. However, if a SMU were to be used, then model generation, battery simulation, and battery cycle testing functionalities could all be accessed with a single instrument.

The New Solution

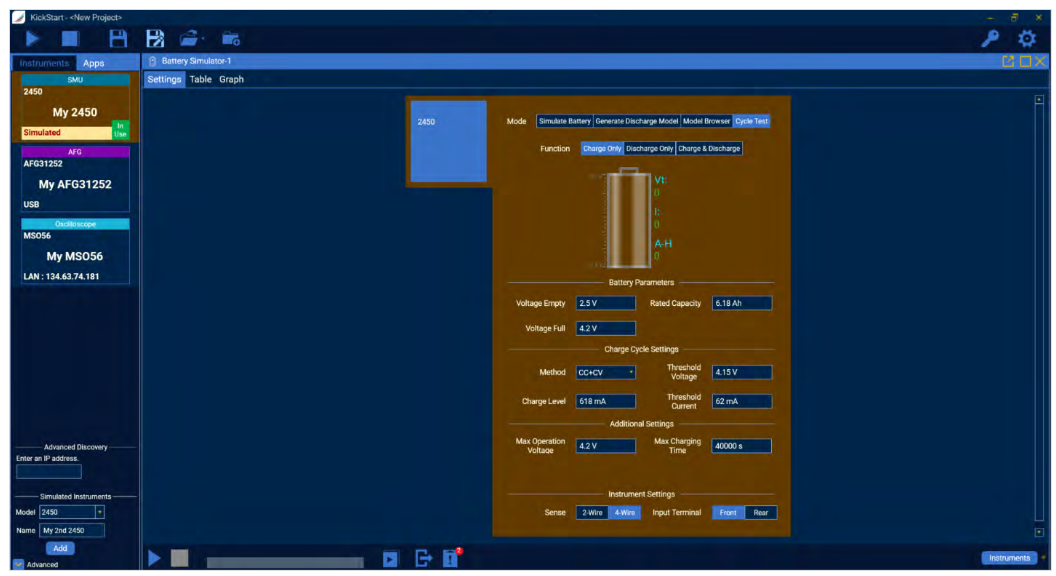

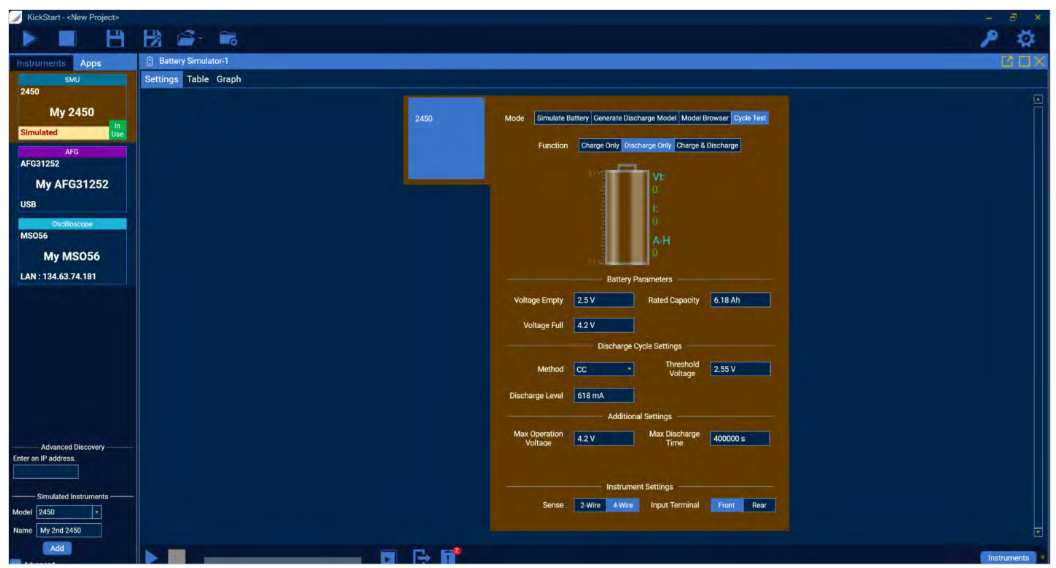

Along with battery model generation and battery simulation capabilities, version 2.11.0 of the KickStart Software Battery Simulator App introduces the ability to perform battery cycling tests using 2400 Graphical Touchscreen and 2600B series SMUs. This can be either as a full charge and discharge cycle, or as just the charge or discharge portions alone.

| Battery Simulation | Battery Discharge Model Generation | Battery Cycle Testing |

| 2281S Battery Simulator | 2380 Series Electronic Loads | - |

| TTI Graphical Series SMUs | TTI Graphical Series SMUs | TTI Graphical Series SMUs |

| 2600B Series SMUs | 2600B Series SMUs | 2600B Series SMUs |

| KickStart Battery Simulator App | ||

Figure 4: Chart explaining which instruments can perform which operations with the Battery Simulator App

In a battery cycling test, the objective is to exercise a battery by charging and discharging it repeatedly to determine when the battery’s total capacity begins to degrade. Thus, battery lifetime can be discerned through a long-term battery cycle test.

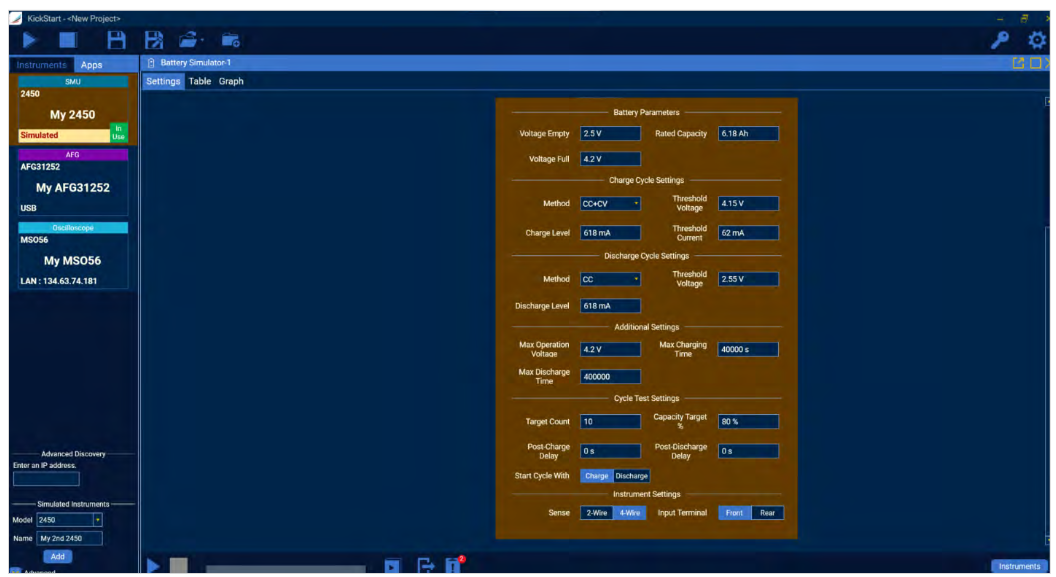

Batteries can be charged or discharged in a few different ways. A charge or discharge cycle may employ a constant current (CC) or constant voltage (CV) method. The CC method simply applies a current bias to the battery to prevent overcurrent charge conditions, while the CV method applies a voltage bias with a steadily decreasing charge current. A hybrid CC + CV method is also available for charge cycles. Hybrid Charge Mode is typically defined by a constant current charge followed by a constant voltage charge. The SMU is placed in a current source mode and supplies a bias to the battery. The battery is charged up to a voltage specified by the Max Operating Voltage/Threshold Voltage parameter, which is where the Source V limit is set. Once the Max Operating Voltage is reached, the SMU operates in compliance mode, and we see the sourced current start to drop. When the sourced current drops to the Threshold Current, the charge is done.

It is also important to consider how long a charge/ discharge cycle should be. If the charging or discharging time drastically differs from what is rated, then significant damage to a battery can be done. Discharging a battery too deeply can crystalize, often permanently, the internal structure of the battery. This, as well as other stresses, cause a decrease in capacity. Conversely, overcharging batteries greatly increases the chance of failure in the form of overheating, bloating, or even thermal runaway and explosion. So, if a cycle does not complete before the Max Charging Time or Max Discharging Time parameters are met, the test will end with a resulting failure message.

As previously stated, a battery is aged via undergoing multiple charge and discharge cycles. The goal is for the total battery capacity to not degrade excessively once aged. Furthermore, an excessive decrease in rated capacity indicates that the battery is damaged or is nearing the end of its lifecycle. This damage increases the chance of battery failure and thermal runaway. The Capacity Target % parameter allows the user to set the percentage of the starting battery capacity which should remain by the end of the test. If the measured battery capacity is lower than the (rated capacity * capacity target %) then the test fails.

Which Solution is Right for My Application?

With so many instrumentation options available, it might be difficult to determine which solution will deliver the best results for your battery test and simulation applications. Each instrument family, or model therein, offers its own advantages due to differences in ranges, accuracy, speed, and noise levels. For example, while the 2400 graphical series SMUs, 2600B series SMUs and the 2281S can source, sink, and measure, all offer the same 6.5-digit resolution, and all offer the same sample interval within KickStart Software, they do have differences in how much voltage, current, or power they can sink. See Figures 5, 6, 7, and 8 for helpful charts listing suggested instrumentation for different battery modeling applications and their specifications.

| CC Discharge | Battery Type | 2450 Graphical SMU | 246x Graphical SMUs | 2470 Graphical SMU | 2600B Series SMUs | 2380 DC Electronic Load |

| ≤10mA | Coin cell | ✅ | ✅ | ✅ | ✅ | ❌ |

| Sleep Modes | Any | ✅ | ✅ | ✅ | ✅ | ❌ |

| 5A | Li-Ion/Li-Po | ❌ | ✅ | ❌ | ❌ | ✅ |

| 1A | ✅ | ✅ | ✅ | ✅ | ✅ |

Figure 5: Table outlining the capabilities of different instrumentation options for model generation

| Charge Current | Battery Type | 2450 Graphical SMU | 246x Graphical SMUs | 2470 Graphical SMU | 2600B Series SMUs | 2281S Battery Simulator |

| <10mA | Coin cell | ✅ | ✅ | ✅ | ✅ | ✅ |

| 5A | Li-Ion/Li-Po | ❌ | ✅ | ❌ | ❌ | ✅ |

| 1A | ✅ | ✅ | ✅ | ✅ | ✅ |

Figure 6: Table outlining the capabilities of different instrumentation options for model simulation

| Specifications | 2461 Graphical SMU | 2281S Battery Simulator |

| Sourcing | 100V;7A(10A Pulse) | 20V;6A |

| Sinking | 100V;7A(10A Pulse) | 20V;1A(Uncontrolled) |

| Voltage Setting Accuracy | ±(0.015% + 200 μV) | ±(0.02% + 3 mV) |

| Current Setting Accuracy | ±(0.025% + 1 nA) | ±(0.05% + 5 mA) |

| Voltage Measurement Accuracy | ±(0.012% + 200 μV) | ±(0.02% + 2 mV) |

| Current Measurement Accuracy | ±(0.025% + 700 pA) | ±(0.04% + 10 μV) |

| Setting Accuracy Resolution | 5 μV and 50 pA | 1 mV and 0.1 mA |

| Measurement Accuracy Resolution | 100 nV and 1 pA | 0.1 mV and 1 0nA |

| Noise Levels | 1 μV (RMS) and 40 pA (RMS) | <1 mV RMS,<6 mV p-p and <3 mA RMS |

| Load Regulations | ±(0.01% + 100 μV),±(0.01% ± 100 pA) | ±(0.01% + 2 mV),±(0.01% ± 0.25 mV) |

| Line Regulations | (0.01%) | ±(0.01% + 1 mV),±(0.01% ± 0.25 mV) |

Figure 7: Table outlining the specifications of the 2461 Graphical SMU and the 2281S Battery Simulator

| 2450 | 2460 | 2470 |

| 200 V;1A | 105 V;7A(7A Pulse)(100 W) | 1100 V;1A(20 W) |

| 200 V;1A | 105 V;7A(7A Pulse)(100 W) | 1100 V;1A(20 W) |

| ±(0.100% + 200 μV) | ±(0.025% + 1 nA) | ±(0.100% + 200 pA) |

| ±(0.100% + 100 pA) | ±(0.015% + 200 μV) | ±(0.02% + 3 mV) |

| ±(0.100% + 150 μV) | ±(0.012% + 200 μV) | ±(0.012% + 200 μV) |

| ±(0.100% + 50 pA) | ±(0.025% + 700 pA) | ±(0.10% + 250 pA) |

| 500 nV and 500 fA | 100 nV and 1 pA | 100 nV and 10 fA |

| 1 μV and 500 fA(RMS)(<10Hz) | 1 μV and 40 pA(RMS)(<10Hz) | 2 μV and 500 fA(RMS)(<10Hz) |

| ±(0.01% + 100 μV),±(0.01% + 100 pA) | ±(0.01% + 100 μV),±(0.01% + 100 pA) | ±(0.01% + 100 μV),±(0.01% + 100 pA) |

| (0.01%) | (0.01%) | (0.01%) |

Figure 8: Table outlining the specifications of the 2450, 2460, and 2470 Graphical SMUs

One of the most significant differences between the 2400 graphical series SMUs and the 2281S is the higher ESR range supported by the 2461 and other SMUs. This higher ESR range allows the SMUs to simulate a greater range of batteries.

Testing an IoT Device with a SMU and Kickstart Software

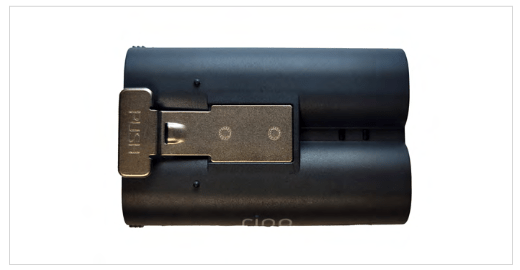

To demonstrate the capabilities of the enhanced KickStart Software Battery Simulator App, as well as of the 2400 graphical series SMUs, a ring wireless security camera was chosen to act as a DUT. First, to begin the characterization and optimization process, a model of the device’s battery needs to be made. To do so, access to the battery cells themselves is needed. Fortunately, the wireless Ring Security Camera uses removeable battery packs.

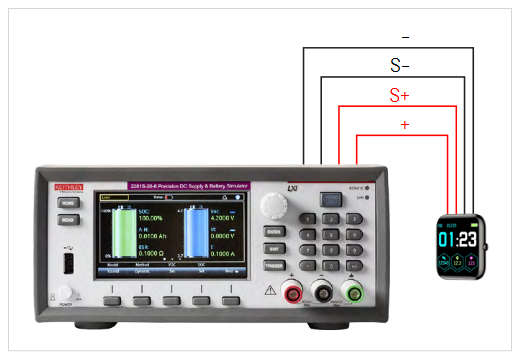

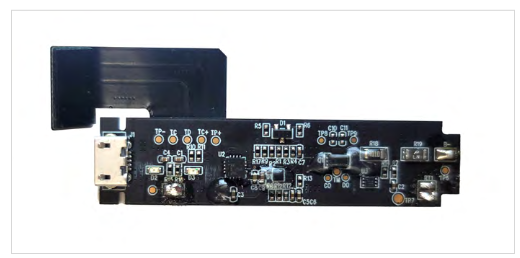

After carefully removing the outer casing of the battery pack, shown in Figure 9, two 18650 lithium-ion batteries, in parallel, along with a battery management system (BMS) board can be seen. The BMS is displayed in Figure 10, while the batteries are shown in Figure 11. Next, the battery is disconnected from the BMS board. From here, a 2450 was connected to the pair of batteries in a four-wire sense connection, similar to that in Figure 3.

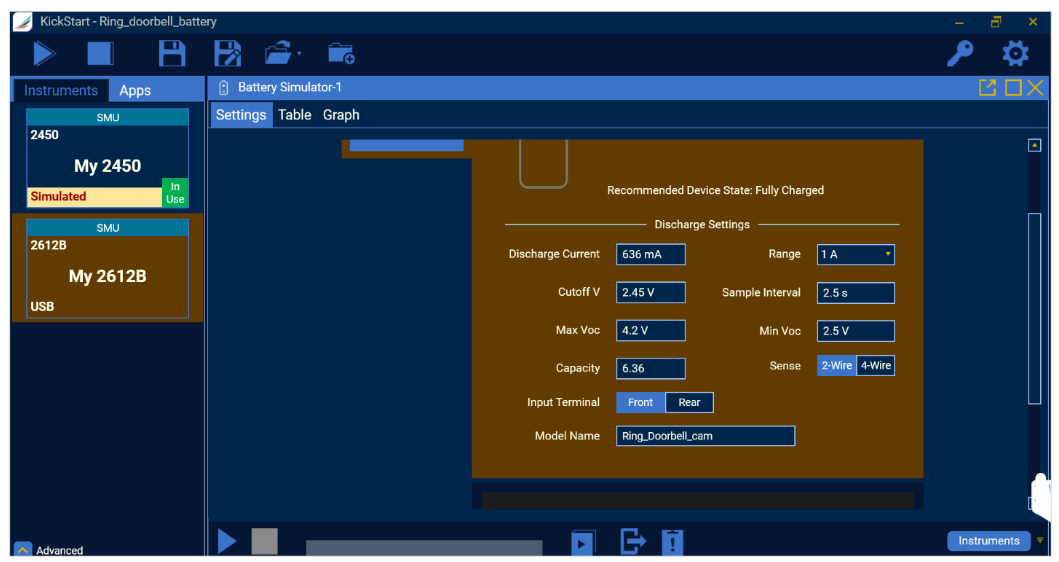

Now that the 2450 is properly connected to the battery, a battery discharge model of the two Li-ion batteries in parallel can be created in a few mouse clicks. From within KickStart Software, clicking the 2450 SMU and then the Battery Simulator App will open the simulate battery window. From here, click on “generate discharge model” to begin entering your model generation settings. As the two 18650 cells are each rated for 3180mAh, the total capacity of the batteries in parallel is 6360 mAh. The settings shown in Figure 12 were chosen for the model generation.

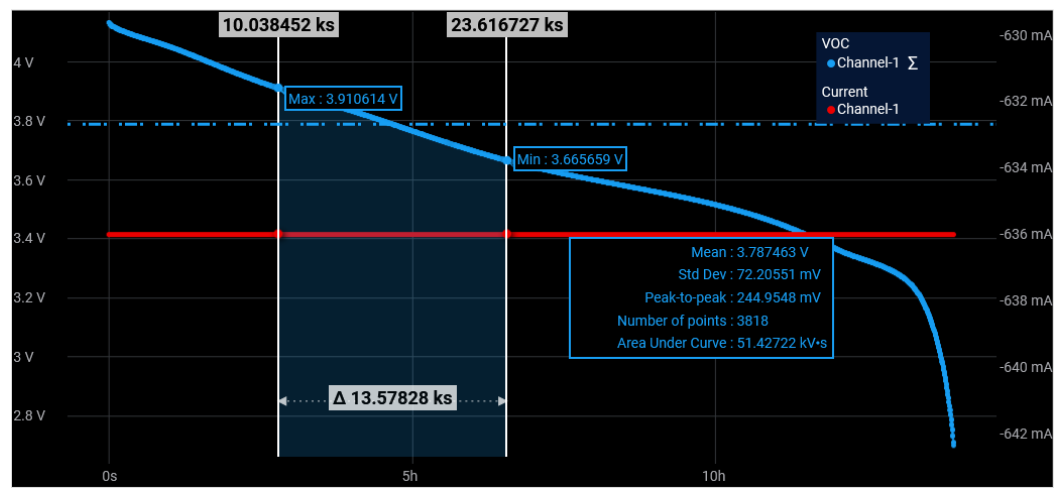

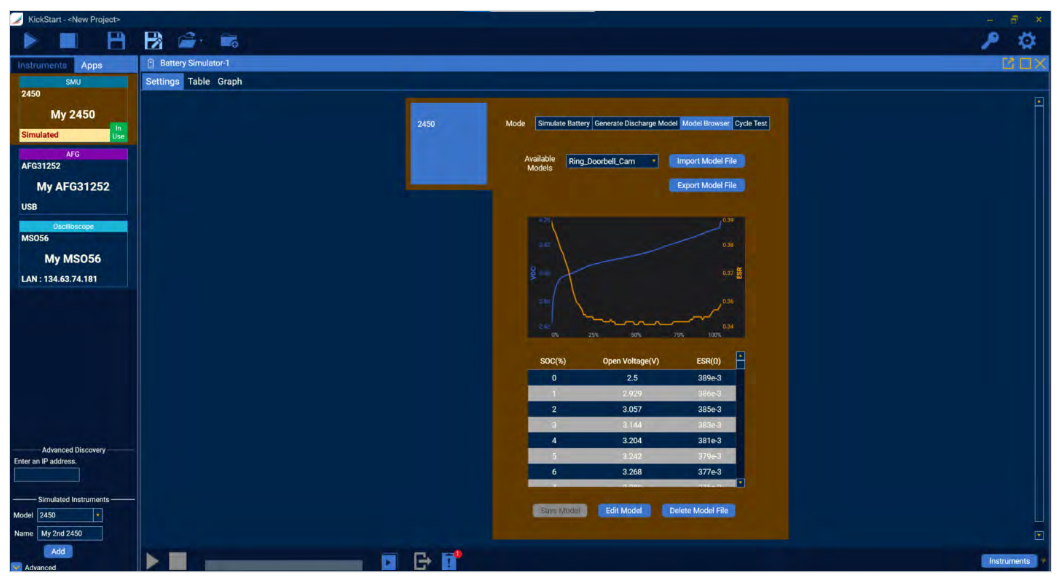

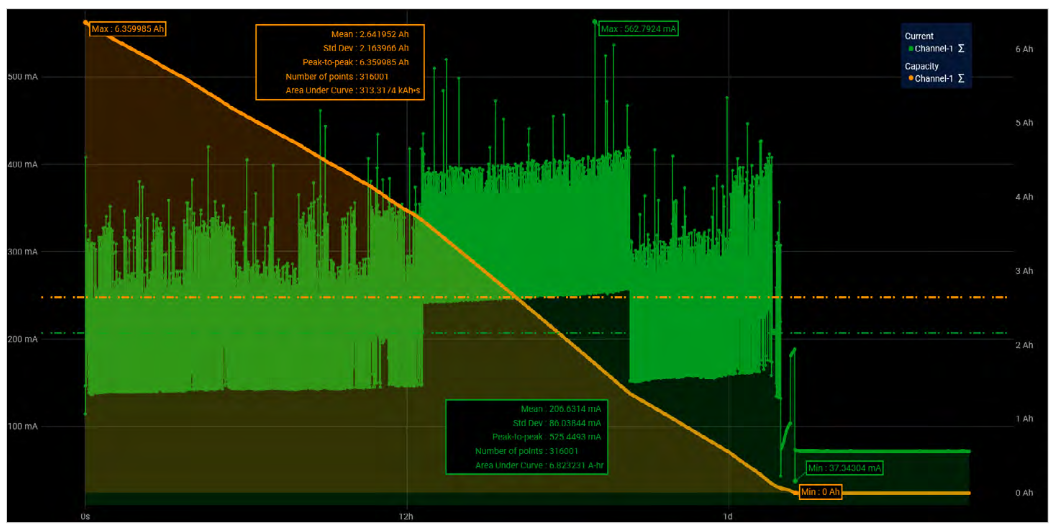

After clicking the run button, the discharge will begin and continue until the Cutoff V parameter is reached. During this time, you can click on the table tab to see a table of every measurement taken by the 2450, as well as some statistics such as the maximum, average, and standard deviation. Next, clicking on the graph tab reveals plots for VOC, ESR, and current. Within the legend you can also see a sigma icon that is used to show or hide statistics. Clicking this button will reveal statistics such as number of points and area under the curve. Cursors can also be added to the graph to easily view timestamps and determine the time between two specified samples. The battery discharge curve and these analysis tools can be seen in Figure 13. The resulting 101-point model can be seen in Figure 14.

| PW_MODEL_PW2281S_20_6 | ||

| Capacity = 6.36 AH | ||

| SOC (%) | Open Voltage (V) | ESR (ohm) |

| 0 | 2.5 | 0.389 |

| 1 | 2.929 | 0.386 |

| 2 | 3.057 | 0.385 |

| 3 | 3.144 | 0.383 |

| 4 | 3.204 | 0.381 |

| 5 | 3.242 | 0.379 |

| 6 | 3.268 | 0.377 |

| 7 | 3.286 | 0.376 |

| 8 | 3.3 | 0.373 |

| 9 | 3.312 | 0.371 |

| 10 | 3.323 | 0.369 |

| 11 | 3.332 | 0.366 |

| 12 | 3.342 | 0.363 |

| 13 | 3.352 | 0.36 |

| 14 | 3.365 | 0.358 |

| 15 | 3.379 | 0.356 |

| 16 | 3.392 | 0.355 |

| 17 | 3.405 | 0.354 |

| 18 | 3.418 | 0.353 |

| 19 | 3.43 | 0.351 |

| 20 | 3.441 | 0.351 |

| 21 | 3.452 | 0.35 |

| 22 | 3.462 | 0.35 |

| 23 | 3.471 | 0.35 |

| 24 | 3.48 | 0.35 |

| 25 | 3.489 | 0.349 |

| 26 | 3.497 | 0.349 |

| 27 | 3.505 | 0.349 |

| 28 | 3.512 | 0.349 |

| 29 | 3.519 | 0.349 |

| 30 | 3.525 | 0.349 |

| 31 | 3.532 | 0.348 |

| 32 | 3.538 | 0.348 |

| 33 | 3.544 | 0.348 |

| PW_MODEL_PW2281S_20_6 | ||

| Capacity = 6.36 AH | ||

| SOC (%) | Open Voltage (V) | ESR (ohm) |

| 34 | 3.55 | 0.348 |

| 35 | 3.555 | 0.349 |

| 36 | 3.561 | 0.348 |

| 37 | 3.567 | 0.348 |

| 38 | 3.572 | 0.347 |

| 39 | 3.577 | 0.347 |

| 40 | 3.583 | 0.347 |

| 41 | 3.588 | 0.347 |

| 42 | 3.594 | 0.347 |

| 43 | 3.599 | 0.347 |

| 44 | 3.605 | 0.348 |

| 45 | 3.61 | 0.348 |

| 46 | 3.616 | 0.348 |

| 47 | 3.622 | 0.348 |

| 48 | 3.628 | 0.348 |

| 49 | 3.634 | 0.347 |

| 50 | 3.641 | 0.347 |

| 51 | 3.647 | 0.347 |

| 52 | 3.654 | 0.348 |

| 53 | 3.661 | 0.348 |

| 54 | 3.669 | 0.348 |

| 55 | 3.676 | 0.347 |

| 56 | 3.684 | 0.347 |

| 57 | 3.693 | 0.347 |

| 58 | 3.701 | 0.347 |

| 59 | 3.71 | 0.347 |

| 60 | 3.719 | 0.347 |

| 61 | 3.728 | 0.347 |

| 62 | 3.737 | 0.348 |

| 63 | 3.747 | 0.348 |

| 64 | 3.756 | 0.347 |

| 65 | 3.766 | 0.347 |

| 66 | 3.776 | 0.347 |

| 67 | 3.785 | 0.347 |

| PW_MODEL_PW2281S_20_6 | ||

| Capacity = 6.36 AH | ||

| SOC (%) | Open Voltage (V) | ESR (ohm) |

| 68 | 3.795 | 0.347 |

| 69 | 3.804 | 0.347 |

| 70 | 3.814 | 0.347 |

| 71 | 3.823 | 0.347 |

| 72 | 3.832 | 0.348 |

| 73 | 3.841 | 0.348 |

| 74 | 3.849 | 0.348 |

| 75 | 3.858 | 0.348 |

| 76 | 3.866 | 0.348 |

| 77 | 3.875 | 0.348 |

| 78 | 3.883 | 0.348 |

| 79 | 3.892 | 0.348 |

| 80 | 3.901 | 0.348 |

| 81 | 3.91 | 0.348 |

| 82 | 3.919 | 0.349 |

| 83 | 3.929 | 0.349 |

| 84 | 3.939 | 0.35 |

| 85 | 3.95 | 0.35 |

| 86 | 3.96 | 0.35 |

| 87 | 3.972 | 0.35 |

| 88 | 3.983 | 0.35 |

| 89 | 3.995 | 0.349 |

| 90 | 4.006 | 0.35 |

| 91 | 4.018 | 0.35 |

| 92 | 4.029 | 0.35 |

| 93 | 4.04 | 0.35 |

| 94 | 4.05 | 0.351 |

| 95 | 4.06 | 0.352 |

| 96 | 4.069 | 0.353 |

| 97 | 4.078 | 0.353 |

| 98 | 4.087 | 0.353 |

| 99 | 4.096 | 0.354 |

| 100 | 4.2 | 0.355 |

Figure 14: 101-point Ring Battery Pack Demo

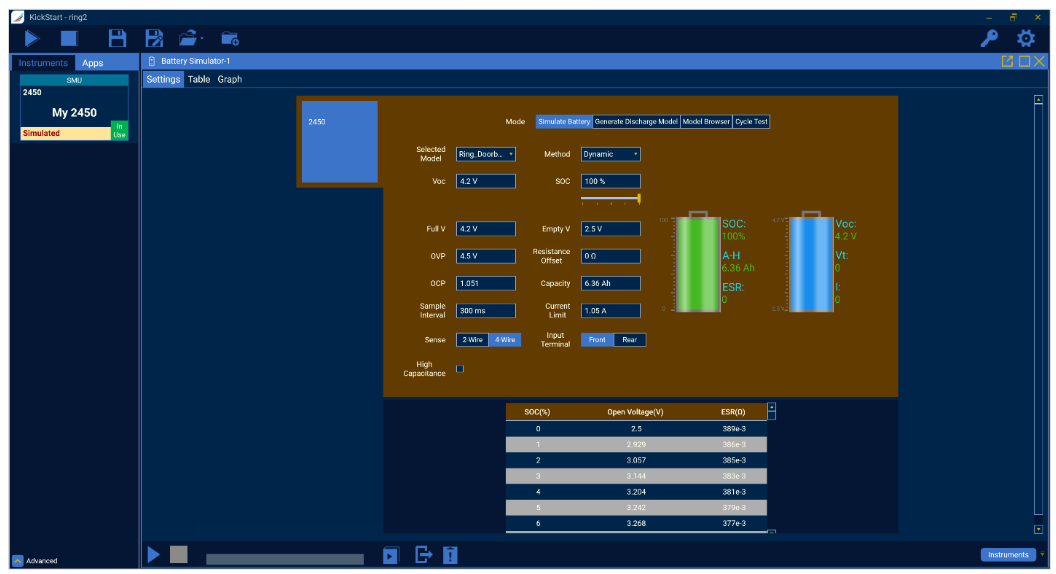

Once the model has been generated, the battery pack can be simulated by the 2450 SMU, allowing it to act in place of the batteries to power the wireless Ring security camera. However, during testing it was discovered that the battery packs included with the Ring security camera come with anti-tamper protections preventing the battery pack from working after being reassembled. To get around this issue, a wired Ring security camera, normally powered by micro-USB, was substituted. The micro-USB cable that plugs into the back of the Ring security camera was cut to reveal the positive and negative power wires. The 2450 was then connected to these exposed wires in a four-wire sense connection similar to what’s shown in Figure 3. From here, the “simulate” tab in the Battery Simulator App was opened, the previously generated battery model, “ring_Doorbell_cam.csv” was chosen, and the settings shown in Figure 15 were applied.

If a battery model is being used and wasn’t generated using KickStart Software, the Model Browser tab allows users to select a model and import it to their local Kickstart Software repository. The model browser also allows for quick modifications to the selected battery model. An example of the model browser tab can be seen in Figure 16. After pressing the run button, the 2450 will begin to simulate the Ring security camera’s battery and power on the device. Just as with the generate discharge model tab, KickStart Software will start to record measurements while simultaneously visualizing this data in the table and graph tabs. However, the graph for battery simulation also allows the user to plot SoC and capacity. The discharge curve of the simulated battery is shown in Figure 17.

Figure 17 illustrates that the current draw increases dramatically when accessing the camera from the Ring App. The section of the graph starting at about 12 hours shows the current draw when manually accessing the camera, while the other spikes show the automatic motion detection function. Also shown in this graph are statistic windows displaying information about each plot. Cursors can also be added to limit the range the statistics window focuses on. These tools make it easier to analyze information such as power usage of DUTs and area under the curve.

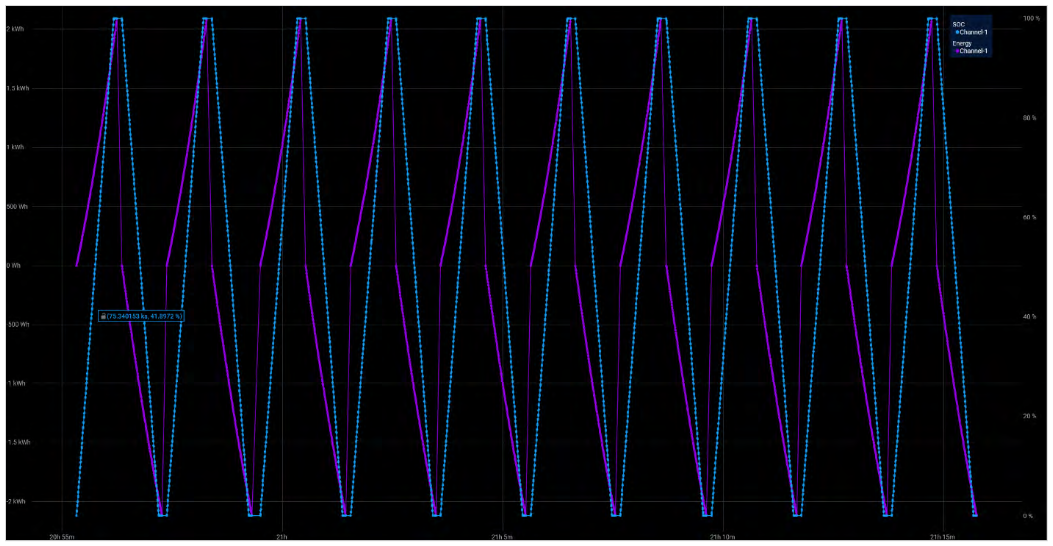

To determine how the Ring Video Doorbell’s battery lifespan degrades across multiple charge and discharge cycles as the battery is depleted and recharged overtime as it is used, the battery pack can be cycle tested using KickStart Software. In the battery cycle test tab, users will set their charge and discharge settings according to their battery specifications. Users will also set parameters such as number of cycles, and capacity target. An example of the battery cycle settings for the Ring battery pack is shown in Figure 18, and the plot of the resulting data is seen in Figure 19.

The battery cycle test mode also includes a table and graph tab to visualize data. If the battery being tested is in-between a full and empty charge, or if the user wants to ensure they are testing from a fully charged or fully depleted battery, a “Charge Only” or “Discharge Only” battery cycle can be run. An example of these settings can be seen in Figures 20 and 21.

Conclusion

The addition of SMUs to the KickStart Software Battery Simulator App broadens the scope of batteries which can be tested alongside a powerful “one-box” solution. KickStart Software enables easy repetition of tests under various conditions and allows for a simple method to generate battery models for simulation. The same SMU can be used to simulate the models and the inclusion of battery charge/ discharge and cycle testing extends the functionality of the app even further, allowing users to test battery longevity alongside device optimization and overall performance. The simplicity afforded by a total software plus instrumentation solution means that it is possible for anyone to set up and run tests quickly and efficiently — from students to technicians to design engineers.

Find more valuable resources at TEK.COM

Copyright © Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks or registered trademarks of their respective companies.

081523 1KW-74029-0